EN10305-5 Welded Square Tubes

The European norm EN 10305-5 specifies the requirements for unalloyed carbon steel welded square and rectangular tubes for precision systems. These tubes are intended for use in the construction of greenhouses, scaffolding and fences and have different specific dimensional tolerances.

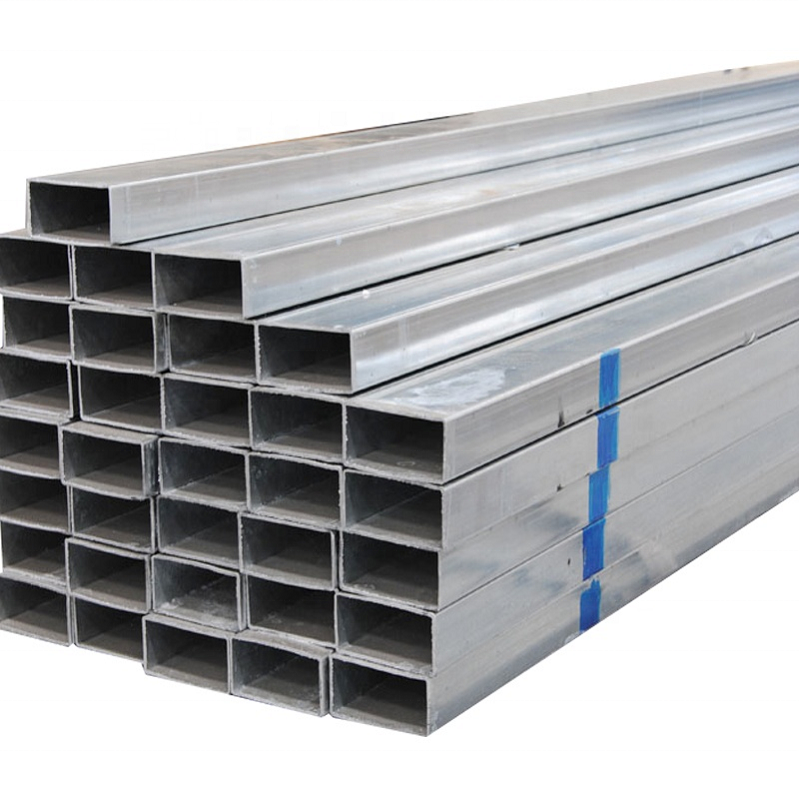

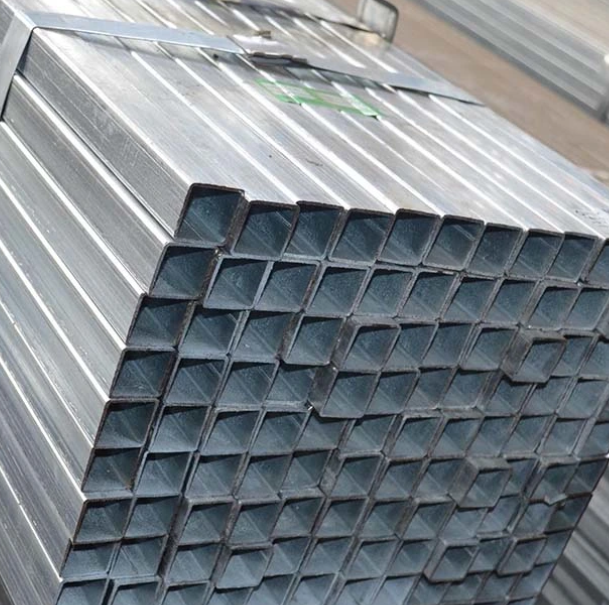

Welded square pipe, also known as welded pipe, is a section steel with a square cross-sectional shape made of hot-rolled or cold-rolled strip or coil as the base material, cold-bending, and then high-frequency welding. The welding square tube has a simple production process, high production efficiency, and many varieties and specifications. Welded pipes with larger diameters can be produced from narrower billets, and welded pipes with different diameters can also be produced from billets of the same width. Welded square pipes with large diameter or thicker are generally made directly from steel billets, while small welded pipes only need to be welded directly by steel strips, then simply polished and drawn.

Welded square pipes manufacturers generally conduct directional production and manufacturing according to specifications. If there are special requirements, it can be explained in advance.

- Description

- Inquiry

Description

Welded square pipe, also known as welded pipe, is a section steel with a square cross-sectional shape made of hot-rolled or cold-rolled strip or coil as the base material, cold-bending, and then high-frequency welding. The welding square tube has a simple production process, high production efficiency, and many varieties and specifications. Welded pipes with larger diameters can be produced from narrower billets, and welded pipes with different diameters can also be produced from billets of the same width. Welded square pipes with large diameter or thicker are generally made directly from steel billets, while small welded pipes only need to be welded directly by steel strips, then simply polished and drawn.

Welded square pipes manufacturers generally conduct directional production and manufacturing according to specifications. If there are special requirements, it can be explained in advance.

The manufacturer of welded square pipe has technical requirements for square pipe process.

Through the process test and process analysis of the welded square pipe specification, it is determined that the butt weld of the welded square pipe adopts double-layer CO2 gas shielded welding. The welding square tube material is H08Mn2SiA, 1.2mm welding wire, and the protective gas is pure CO2 gas. The welding square tube current of the first layer of welding seam is 200-250A, the second layer is 240-320A, and the arc voltage is 24-26V. The process requirements are: the first layer of welding seam must be penetrated to ensure that the back is well formed. The welding current, arc voltage, wire feeding speed and welding speed of the square tube can be adjusted according to the equipment model.

The narrow blank of welded square pipe can produce the welded pipe with larger pipe diameter, and the blank with the same width can also produce the welded pipe with different pipe diameter. However, compared with the straight seam square pipe with the same length, the weld length increases by 30 ~ 100%, and the production speed is low.

Welded square pipes with large or thick diameter are generally made of steel blank directly, while small welded pipes and thin-walled welded pipes only need to be welded directly through steel strip. Then after simple polishing, wire drawing can be used.Therefore, straight seam welding is mostly used for small-diameter welded pipes, while spiral welding is mostly used for large-diameter welded pipes.

Most welded square pipes manufacturers in China will adopt the above process.

Product Name | Galvanized square pipe | |||

Specifications | Square pipe: 20*20mm~600*600mm Thickness: 1.2mm~20mm Length: 2.0m~12m | |||

Material | Low carbon steel | |||

Steel Grade | Q195 = S195 / A53 Grade A Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 Q355 = S355JR / A500 Grade B Grade C | |||

Standard | EN10219, EN10210 GB/T 6728 JIS G3466 ASTM A500, A36 | |||

Surface Anti-rusty Coating | pre-galvanized (Zinc coating: 40-80g/m2) hot dipped galvanized (Zinc coating: 200-600g/m2 ) | |||

Pipe Ends | Plain ends | |||

Certificates | ISO 9001 /TUV/SGS/BV | |||

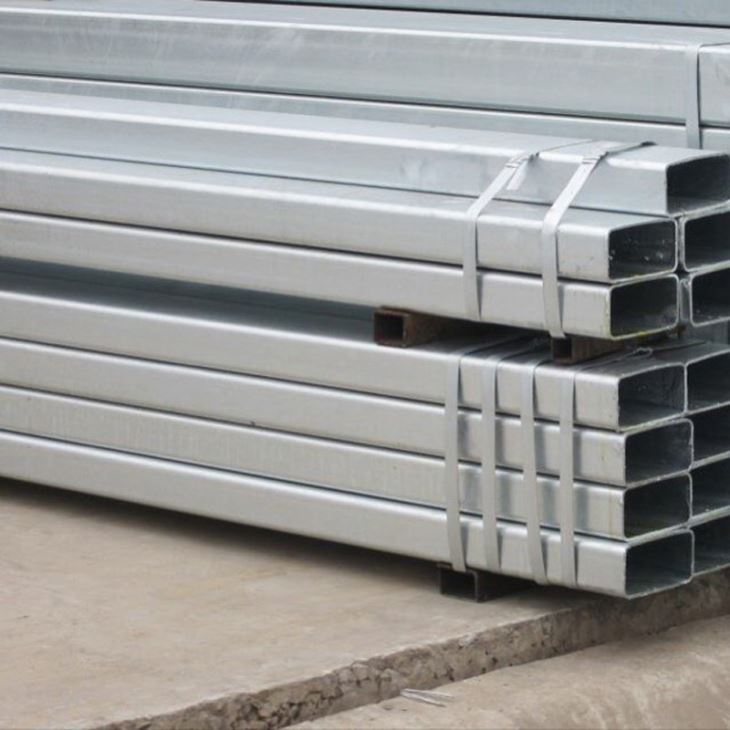

Packing and Shipment | 1. OD 200mm and below In hexagonal seaworthy bundles packed by steel strips, With two nylon slings for each bundles 2. above OD 200mm in bulk or according to custom opinion 3. 23 tons/container and 5 tons/size for a trial order; 4. For 20″ container the max length is 5.8m; 5. For 40″ container the max length is 11.8m. | |||

Usage | Construction / building materials steel pipe Structure steel pipe Solar structure component steel pipe Fence post steel pipe Greenhouse frame steel pipe | |||

Trade terms | FOB, CFR, CIF, EXW, etc | |||

Payment terms | T/T, | |||

Delivery time | 15-45 days (based on quantity) after receiving advanced payment by T/T | |||

Main market | Southeast Asia, South Asia, Middle East, Europe, South America,etc | |||

parties.Professional inspection is provide to ensure that the weight of the goods is sufficient.

Square Pipe size chart | ||||

Square Hollow Section | Thickness | |||

20*20 25*25 30*30 | 1.2-3.0 | |||

40*40 50*50 | 1.2-4.75 | |||

60*60 | 1.2-5.75 | |||

70*70 80*80 75*75 90*90 100*100 | 1.5-5.75 | |||

120*120 140*140 150*150 | 2.5-10.0 | |||

160*160 180*180 200*200 | 3.5-12.0 | |||

400*400 280*280 450*300 450*200 | 5.0-20.0 | |||

250*250 300*300 400*200 350*350 350*300 | 4.5-15.75 | |||