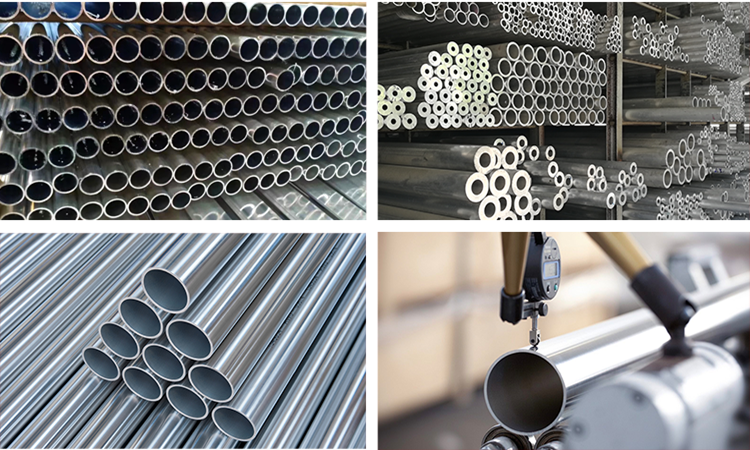

Thick Wall Seamless Aluminium Tubes

Aluminum tube is a kind of non-ferrous metal tube, which is made of pure aluminum or aluminum alloy by extrusion into a hollow metal tubular material along its longitudinal full length.There can be one or more closed through holes with uniform wall thickness and cross section, which can be delivered in straight line or roll shape.

Characteristics: it is a kind of high-strength hard aluminum, which can be strengthened by heat treatment. It has medium plasticity in annealing, rigid quenching and thermal state, and good spot welding. When gas welding and argon arc welding are used, the aluminum tube tends to form intergranular cracks; The machinability of aluminum tube after quenching and cold work hardening is good, but it is poor in annealing state. The corrosion resistance is not high. Anodizing and painting methods or aluminum coating on the surface are often used to improve the corrosion resistance. It can also be used as mold material.

- Description

- Inquiry

Description

Aluminum tube.

It is a kind of high-strength hard aluminum, which can be heat-treated and strengthened. It has medium plasticity in annealing, quenching and hot state. It has good spot weldability. The aluminum tube has the tendency to form intergranular cracks when using gas welding and argon arc welding. After quenching and cold work hardening, the machinability is good and it is not good in the annealed state. The corrosion resistance is not high, and the anodizing treatment and painting method or the surface is coated with an aluminum layer to improve the corrosion resistance. It can also be used as a mold material.

Aluminum tube advantages:

1 – the advantages of welding technology: thin-walled copper-aluminum tube welding technology suitable for industrial production, known as the world-class problem, is the key technology for the aluminum-based copper of the air-conditioner connecting tube.

2 – the service life advantage: from the inner wall of the aluminum tube, since the refrigerant does not contain moisture, the inner wall of the copper-aluminum connecting tube does not corrode.

3 – the energy-saving advantage: the connecting line between the indoor unit and the outdoor unit of the air conditioner, the lower the heat transfer efficiency, the more energy-saving, or the better the heat insulation effect, the more power-saving.

4 – excellent bending performance, easy to install, transfer machine

Surface finish editing.

1 – Chemical treatment: oxidation, electrophoretic coating, fluorocarbon coating, powder coating, wood grain transfer

2 – Mechanical treatment: mechanical drawing, mechanical polishing, sand blasting

If any questions,you are more than welcome to contact sales@tubesolutions.com.cn