Titanium Capillary Tubes

Titanium Capillary Tubes

Titanium tubing are delivered in straight lengths or as U-bent tubing. Titanium spiral tubing, titanium capillary tubing are available by requirement. All the Titanium Tubing offered by us will pass strict test process.

Features:Low density, High specific strength, Excellent corrosive resistance, No Rust, Good thermal stability, Good thermal conductivity, Biological features, Plasticity, etc.

Applications:Industry field, aerospace, architectural, automotive, biomedical, chemical processing, marine, military, oil, tooling, racing.Heat exchangers and condensers,All kinds of corrosive fluid transmission pipeline system,Titanium bicycle tube, automobile exhaust pipe,Offshore aquaculture

Titanium capillary tubing is a thin, hollow tube made from pure titanium or titanium alloys. It has a small diameter and a thin wall, making it ideal for applications that require precise fluid delivery and control. The tubing is available in different sizes, ranging from micrometer to millimeter diameters, and can be customized to meet specific application requirements.

As a leading manufacturer and supplier of titanium tubes, Grand offers a wide range of titanium capillary tubing products that are designed for different applications and requirements. Our tubes are made from high-quality titanium alloy materials (such as Grade 2, 5, and 9), and are available in various sizes, lengths, and shapes (such as round, square, and rectangular).

- Description

- Inquiry

Description

Titanium tubes– Aerospace Applications

Titanium is used in engine applications such as rotors, compressor blades, hydraulic system components and nacelles. Titanium 6AL-4V alloy accounts for almost 50% of all alloys used in aircraft applications.

Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high temperatures without creeping, titanium alloys are used in aircraft, armor plating, naval ships, spacecraft, and missiles. For these applications titanium alloyed with aluminium, vanadium, and other elements is used for a variety of components including critical structural parts, fire walls, landing gear, exhaust ducts (helicopters), and hydraulic systems. In fact, about two thirds of all titanium metal produced is used in aircraft engines and frames.

Titanium tubes– Industrial Applications

Titanium is used in engine applications such as rotors, compressor blades, hydraulic system components and nacelles. Titanium 6AL-4V alloy accounts for almost 50% of all alloys used in aircraft applications.

Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high temperatures without creeping, titanium alloys are used in aircraft, armor plating, naval ships, spacecraft, and missiles. For these applications titanium alloyed with aluminium, vanadium, and other elements is used for a variety of components including critical structural parts, fire walls, landing gear, exhaust ducts (helicopters), and hydraulic systems. In fact, about two thirds of all titanium metal produced is used in aircraft engines and frames.

Titanium tubes– Consumer and Architectural Applications

Titanium metal is used in automotive applications, particularly in automobile or motorcycle racing, where weight reduction is critical while maintaining high strength and rigidity. Titanium is used in many sporting goods: tennis rackets, golf clubs, lacrosse stick shafts, cricket, hockey, lacrosse and football helmet grills, and bicycle frames and components. Titanium alloys are also used in spectacle frames. The two most common Titanium alloys used in the cycling industry are 6AL-4V (Grade 5) and 3AI-2.5V (Grade). These two different alloys are both high strength Titanium and are both fairly common in the Industry.

Titanium tubes– Medical Applications

Because it is bio-compatible (non-toxic and is not rejected by the body), Titanium is used in different medical applications including surgical implements and implants, such as hip balls and sockets (joint replacement) that can stay in place for up to 20 years. Titanium has the inherent property to osseointegrate, enabling use in dental implants that can remain in place for over 30 years. This property is also useful for orthopedic implant applications. Titanium is also used for the surgical instruments used in image-guided surgery, as well as wheelchairs, crutches, and any other products where high strength and low weight are desirable. The unique qualities of titanium also prove to be MRI (Magnetic Resonance Imaging) and CT (Computed Tomography) compatible.

Name | Titanium Capillary Tubes |

Standard | ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928 |

Material Grade | Gr1, Gr2, Gr4, Gr7, Gr9, Gr11, Gr12, etc |

Length | short cut or standard length or coil |

Size(mm) | Out Diameter 1.00-8.00mm |

Section shape | Round / Square,etc |

Tolerance | a) Outer Diameter: +/- 0.05mm |

b) Thickness: +/- 0.05mm | |

c) Length: +/- 0.5mm | |

Surface | Pickling, annealing, polishing, bright. |

Feature | 1.Low Density and High Strength 2.Excellent Corrosion Resistance 3.Good resistance to effect of heat 4.Excellent Bearing to cryogenic property 5.Nonmagnetic and Non-toxic 6.Good thermal properties 7.Low Modulus of Elasticity |

Test | Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

Titanium capillary tubing is a thin, hollow tube made from pure titanium or titanium alloys. It has a small diameter and a thin wall, making it ideal for applications that require precise fluid delivery and control. The tubing is available in different sizes, ranging from micrometer to millimeter diameters, and can be customized to meet specific application requirements.

As a leading manufacturer and supplier of titanium tubes, Grand offers a wide range of titanium capillary tubing products that are designed for different applications and requirements. Our tubes are made from high-quality titanium alloy materials (such as Grade 2, 5, and 9), and are available in various sizes, lengths, and shapes (such as round, square, and rectangular).

Titanium Capillary Tube

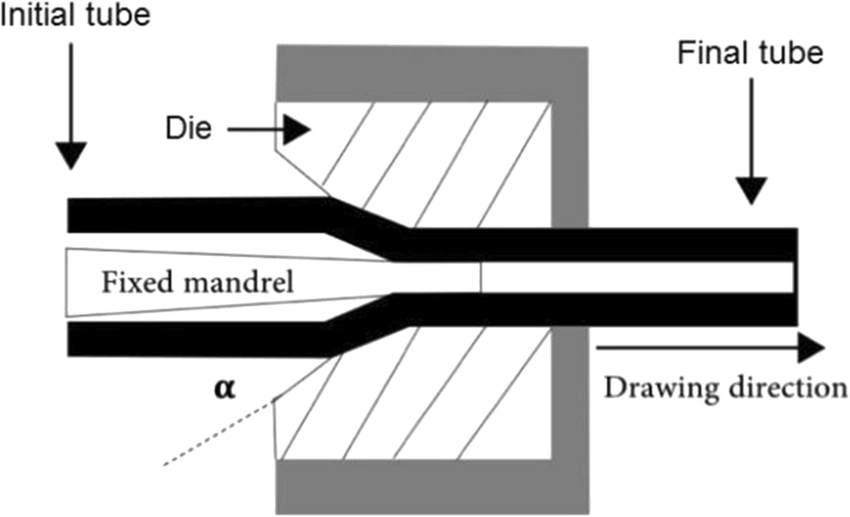

Titanium capillary tubes are typically produced using a process called cold drawing.

The process involves the following steps:

- Tube preparation: The first step is to prepare the titanium tube for the cold drawing process. This may involve cleaning the tube to remove any surface contaminants or applying a lubricant to reduce friction during the drawing process.

- Tube insertion: The tube is inserted into the draw bench, which consists of a series of dies of decreasing diameter. The tube is held in place by a gripping device, such as a collet, which is attached to a chain or wire rope.

- Tube drawing: The gripping device pulls the tube through the first die, which compresses the tube and reduces its diameter while increasing its length. The tube is then pulled through subsequent dies, each of which has a smaller diameter than the previous die.

- Annealing: After a few passes through the draw bench, the titanium tube may become work-hardened and brittle. To prevent cracking or failure, the tube is annealed, which involves heating the tube to a specific temperature and then slowly cooling it to room temperature. This process relieves stress and softens the material, making it easier to draw through the remaining dies.

- Final pass and finishing: The titanium tube may go through several rounds of drawing and annealing until the desired diameter and length are achieved. After the final pass through the draw bench, the tube may be cut to the desired length and undergo finishing processes, such as polishing or cleaning.

The application of Titanium Capillary Tubes

Titanium capillary tubes are typically used in applications where precise and small-diameter tubing is required. Some common applications for titanium capillary tubes include:

- Medical devices: Titanium capillary tubes are used in various medical devices such as biopsy needles, catheters, marker bands and endoscopes due to their biocompatibility, corrosion resistance, and strength-to-weight ratio.

- Chromatography: Titanium capillary tubes are used as columns in gas chromatography and liquid chromatography due to their high strength, corrosion resistance, and low reactivity with chemical compounds.

- Aerospace and aviation: Titanium capillary tubes are used in the aerospace and aviation industry as fuel and hydraulic lines, and other small diameter tubing where lightweight, high strength and corrosion-resistant material is required.

- Precision instruments: Titanium capillary tubes are used in the manufacturing of various precision instruments such as sensors, probes, and measurement equipment due to their strength, durability and resistance to corrosion.

- Electronics: Titanium capillary tubes are used in various electronic applications as wire insulation, heating elements, or as components for electronic sensors.