Stainless Flange

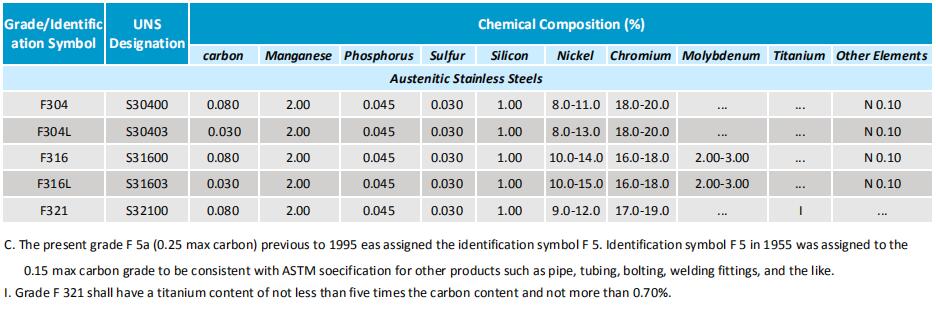

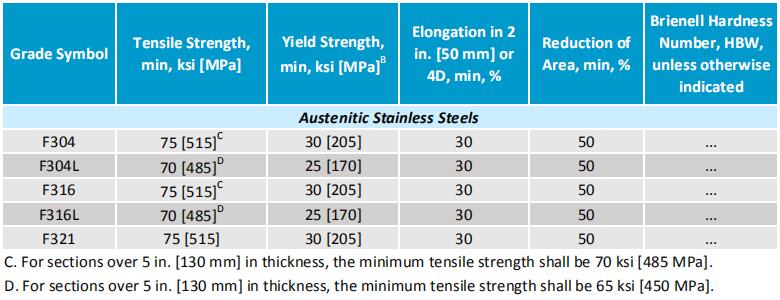

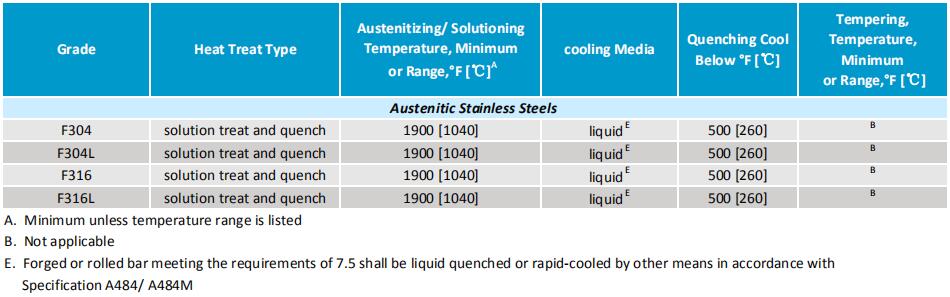

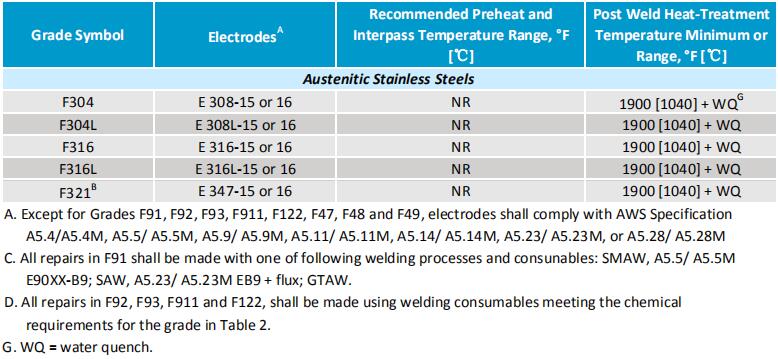

Stainless steel flange simplified as SS flange, it refers to the flanges that made of stainless steel. Common material standards and Grades are ASTM A182 Grade F304/L and F316/L, with pressure ratings from Class 150, 300, 600 etc and to 2500. It used in more industries than carbon steel as stainless steel has better resistant performances on corrosion environment and always provides with a good appearance.

Flange is the parts which connects two pipe ends, flange connection is defined by the flange, gasket and bolt three are connected as a group of combined sealing structure of the detachable connection. The gasket is added between the two flanges and then fastened by bolts. Different pressure flange, thickness is different, and the bolts they use are different, when pump and valve onnect with pipe, the parts of the equipment are also made of the corresponding flange shape, also known as flange connection, usually closured bolted connection parts are also known as flanges, such as the connection of ventilation pipe, this kind of parts can be called “flange type part”, but this connection is only part of a device, such as the connection between flange and water pump, it’s not inapposite to call water pump as flange type parts,but relative small valve,it can be called as flange type parts

If you have any questions, please feel free to contact us

- Description

- Inquiry

Description

Stainless steel flange simplified as SS flange, it refers to the flanges that made of stainless steel. Common material standards and Grades are ASTM A182 Grade F304/L and F316/L, with pressure ratings from Class 150, 300, 600 etc and to 2500. It used in more industries than carbon steel as stainless steel has better resistant performances on corrosion environment and always provides with a good appearance.

Flange is the parts which connects two pipe ends, flange connection is defined by the flange, gasket and bolt three are connected as a group of combined sealing structure of the detachable connection. The gasket is added between the two flanges and then fastened by bolts. Different pressure flange, thickness is different, and the bolts they use are different, when pump and valve onnect with pipe, the parts of the equipment are also made of the corresponding flange shape, also known as flange connection, usually closured bolted connection parts are also known as flanges, such as the connection of ventilation pipe, this kind of parts can be called “flange type part”, but this connection is only part of a device, such as the connection between flange and water pump, it’s not inapposite to call water pump as flange type parts,but relative small valve,it can be called as flange type parts .

Quick introduction of Slip on Raised face flange | |

Item | Stainless steel flange,stainless steel pipe flange |

Standard | ANSI, ASME, DIN, BS, JIS, GB, ISO etc |

Material | 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L,302, 301,201,202,405,410,420,430,904L etc |

Type | Plate Flange, Flat Flange, Slip on Flange, Welding Neck Flange, Long Welding Neck Flange, Blind Flange, Socket Welding Flange, Thread Flange, Screwed Flange, Lap Joint Flange,etc |

Connection type | Raised Face, Flat Face, Ring Type Joint, Lap-Joint Face, Large Male-Female, Small Male-Female,Large tongue groove, Small tongue groove etc |

Size | 1” and 1/2” ~ 120” (DN40-DN3000) |

MOQ | 1 piece |

Price term | EXW factory, FOB, C&F and CIF |

Payment term | T/T, L/C, West Union, Money Gram and etc |

Export to | USA,Canada,Australia,Singapore,Indonesia,Hongkong,Oman,Vietnam etc |

Package | Standard export wooden case or as you requested |

Application | constructions,petroleum, chemical industry, power, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc. |